Characteristics of the horizontal axis metal centrifugal pumps.

Horizontal axis centrifugal pumps

Some of the models the company produces are listed here

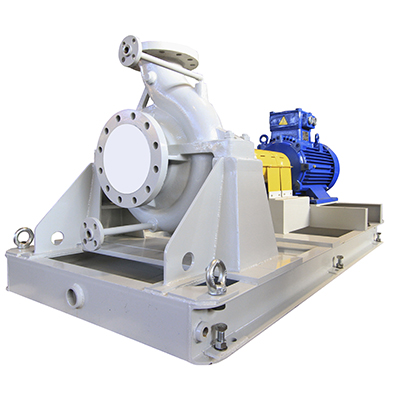

FX Series Pump

FN Series Pump

FXM Series Pump

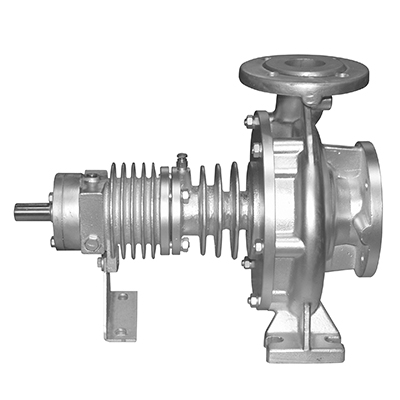

FNM Series Pump in lantern bracket solution

FC Series Pump

FNA Series Pump

FQ Series Pump

CONSTRUCTION

Horizontal axis centrifugal pump with rotor shaft supported by 2 bearings for severe service. Depending on the dimensions of the pump, set-back Vortex, open or wide passage channel impellers are available. Coupling to the electric motor is achieved by means of an elastic fitting and the unit is mounted on a carbon steel frame.

CONSTRUCTION MATERIALS

Cast iron, spheroidal cast iron, bronze, AISI 316, Duplex, Hastelloy-C; whole coverings in Halar (ECTFE) for chemical applications, series coated in anti-abrasive rubber. Single and double mechanical seals with all types of flushing depending on the application requirements. Shaft seal on request.

Hydraulic identifications:

FX set-back vortex impellers

FN open impellers

FC channel impellers

FNA open self-priming impeller

FQ open impeller with rubber coated hydraulic

Lantern bracket and monoblock solutions coupled by means of rigid fitting to IEC standardised motor.

APPLICATIONS

Transfer of soiled, waste and faecal water, seawater with sand, corrosive liquids containing abrasive particles and coarse solids.

USES

CS Series Pump

CS duplex Series Pump

CSM Series Pump

CSL Series Pump

CI Series Pump

CSA Series Pump

EN 733 standardised horizontal pumps

CS Series

CONSTRUCTION

EN 733 standardised centrifugal pumps, complete disassembly of the rotor without the need to disassemble the piping. DIN 24960 (ISO 3069) mechanical seals, standard UNI 2236 PN 10 Flanging, spacing elastic fitting on request. Body, cover and impeller in G25 cast iron (on request bronze or AISI 316). Rotor shaft in AISI 431. Ball bearings lubricated with grease or with oiler at constant level. Mechanical seals can be personalised in terms of material and type of cooling.

CSM Series

CONSTRUCTION

Monoblock centrifugal pumps with body standardised in accordance with EN 733 standards that allow complete disassembly of the motor unit, avoiding disassembly of the pump from the piping. Standard UNI 2236 PN 10 Flanging. Body, cover and impeller in cast iron (on request bronze or AISI 316). Rotor shaft in AISI 431. Mechanical seals can be personalised in terms of materials. Asynchronous three-phase motor with standard IP55 protection in class F insulation.

CSL Series

CONSTRUCTION

Monoblock centrifugal pumps with CS series hydraulic with lantern coupling to IEC standardised motor.

CI Series

CONSTRUCTION

Standardised DIN EN 22858 process centrifugal pumps. Spheroidal cast iron, AISI 316, bronze.

Single, opposing double seals in tandem with all types of flushing.

USES

CSA Series

CONSTRUCTION

API 610 compliant process centrifugal pumps.

USES

• Petrochemical industry

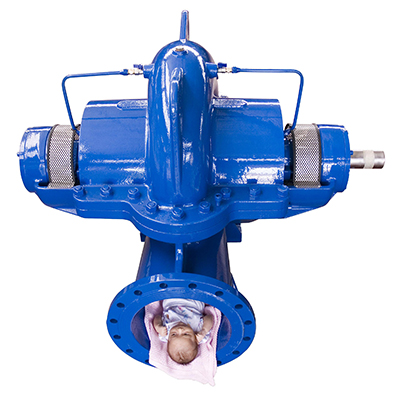

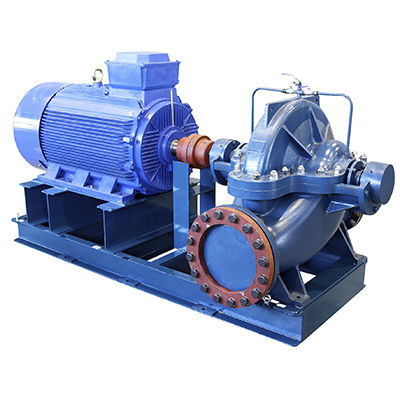

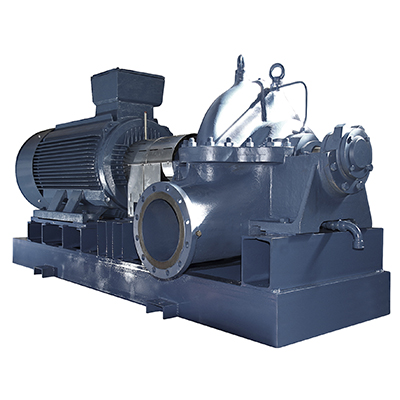

SC Series Pump

SC Series Pump

SC Series Pump

SC Series Pump

CONSTRUCTION

Horizontal axis centrifugal with inlets in line, split-case, with rotor shaft supported by 2 bearings for extremely severe service. The particular conformation of the pump allows maintenance to be carried out quickly and without disassembling the piping. In fact, the impeller can be inspected and freed of any foreign bodies and the bearings and seals can be replaced without moving the pump body. Coupling to the electric motor is by means of an elastic fitting. The unit is mounted on a carbon steel frame. Operating pressure up to 25 Bar.

API 610 solutions on request.

MATERIALS

Construction in cast iron, spheroidal cast iron, bronze, AISI 316, Duplex, Monel, shaft seal or EN 12756 mechanics.

APPLICATIONS

Handling of water, seawater or corrosive liquids that do not contain abrasive particles.

USES

M Series Pump

M-E Series Pump

Series of multistage pumps with star impellers, intakes facing upward, self-priming for low flow rates and high pressures.

MATERIALS

spheroidal cast iron, AISI 316, bronze.

USES

KM Series Pump

K Series Centrifugal Pump

K Series Centrifugal Pump

KM Inox Series Pump

KMV Inox Series Pump

KM Series

Completely revamped series of multistage horizontal axis pumps with double shaft support and closed impellers. Statically and dynamically balanced impellers. The intake and delivery ports can be directed to your liking. Simple shaft seals with cooling chamber or EN 12756 mechanics. Shafts come standard with wear bushings Large size grease-lubricated bearings. Wear rings for body and intermediate stages on request.

- Delivery ports: from DN 32 to DN 200 PN 64

- Flow rate: up to 700 m3/h

- Head: up to 400 m

- Temperatures: from - 10° C up to 140° C

- Operating pressure: up to 50 Bar

- Available construction materials:

- Cast iron, Spheroidal cast iron, Bronze, Steel

KM-V Series

Completely new series of multistage vertical axis pumps with closed impellers. Statically and dynamically balanced impellers. B5 shape lantern fitting to IEC motor and elastic joint. Simple shaft seals or EN 12756 mechanics. Shaft comes standard with wear bushings supported with bushing lubricated with pumped liquid in suction and large grease-lubricated head bearing. Wear rings for body and intermediate stages on request.

- Delivery ports: from DN 32 to DN 150 PN 40

- Flow rate up to 400 m3/h

- Head up to 350 m

- Temperatures from - 10° C up to 120° C

- Operating pressure: up to 40 Bar

- Available construction materials:

- Cast iron, Spheroidal cast iron, Bronze, Carbon Steel, AISI 316

- AISI 316L

KM-E Series

Completely new series of multistage horizontal axis pumps with axial suction and closed impellers. Statically and dynamically balanced impellers. Simple shaft seals or EN 12756 mechanics. Shafts come standard with wear bushings Large size grease-lubricated bearing. Wear rings for body and intermediate stages on request.

- Delivery ports: from DN 80 to DN 150 PN 40

- Flow rate: up to 400 m3/h

- Head: up to 300 m

- Temperatures: from - 10° C up to 110° C

- Operating pressure: up to 40 Bar

- Available construction materials:- Cast iron, Spheroidal cast iron, Bronze, Carbon Steel,

- AISI 316, AISI 316L

USES

FNY Series Pump

FNY Series Pump

FNY Series Pump

CONSTRUCTION

Horizontal axis centrifugal pump standardised in accordance with EN 733 standard with finned support for high heat dispersion with rotor shaft supported by 2 bearings for severe operation grease-lubricated. Design pressure and flanging PN16. Coupling by means of elastic fitting to electric motor with EN 294 compliant fitting cover. Frame in carbon steel. Volute, impeller, cover, plate and wear rings and bearings support in spheroidal cast iron, shaft in AISI 420, mechanical seal standardised in accordance with EN 12756. Version with volute and impeller in carbon steel available on request.

APPLICATIONS

Transfer of heating oil heated up to 320°C not containing aggressive chemical substances or abrasive particles.

USES

CT Series Pump

CT bronze Series Pump

CT-V Series Pump

CONSTRUCTION

“CT” series vertical axis centrifugal pump with closed impeller and in-line ports. The “Pullback” solution allows disassembly of the pump without disconnecting the volute from the piping. The fitting lantern bracket houses the IEC standardised electric motor in B5 form that is coupled by means of telescope rotor shaft to the impeller. The mechanical seal is standardised in accordance with standard EN 12756.

CONSTRUCTION MATERIALS

Cast iron, Spheroidal cast iron, Bronze, Carbon Steel, AISI 316, Duplex; mechanical seals in various materials depending on the pumped fluid.

Depending on the dimensions, three different construction forms are anticipated. Maximum body pressure 16 Bar. Operating temperature up to 110° in standard solution, Port dimensions up to DN 200, flanging PN16 in accordance with ISO 7005. ANSI boring on request.

The unit is mounted on a removable cast iron frame.

Version with independent support and CT-V cooling coil.

APPLICATIONS

Clean water circulation and pumping, water supply systems, seawater, corrosive liquids not containing abrasive particles and solids.

USES

Special solution with bearings support and elastic spacer fitting for marine Sector.